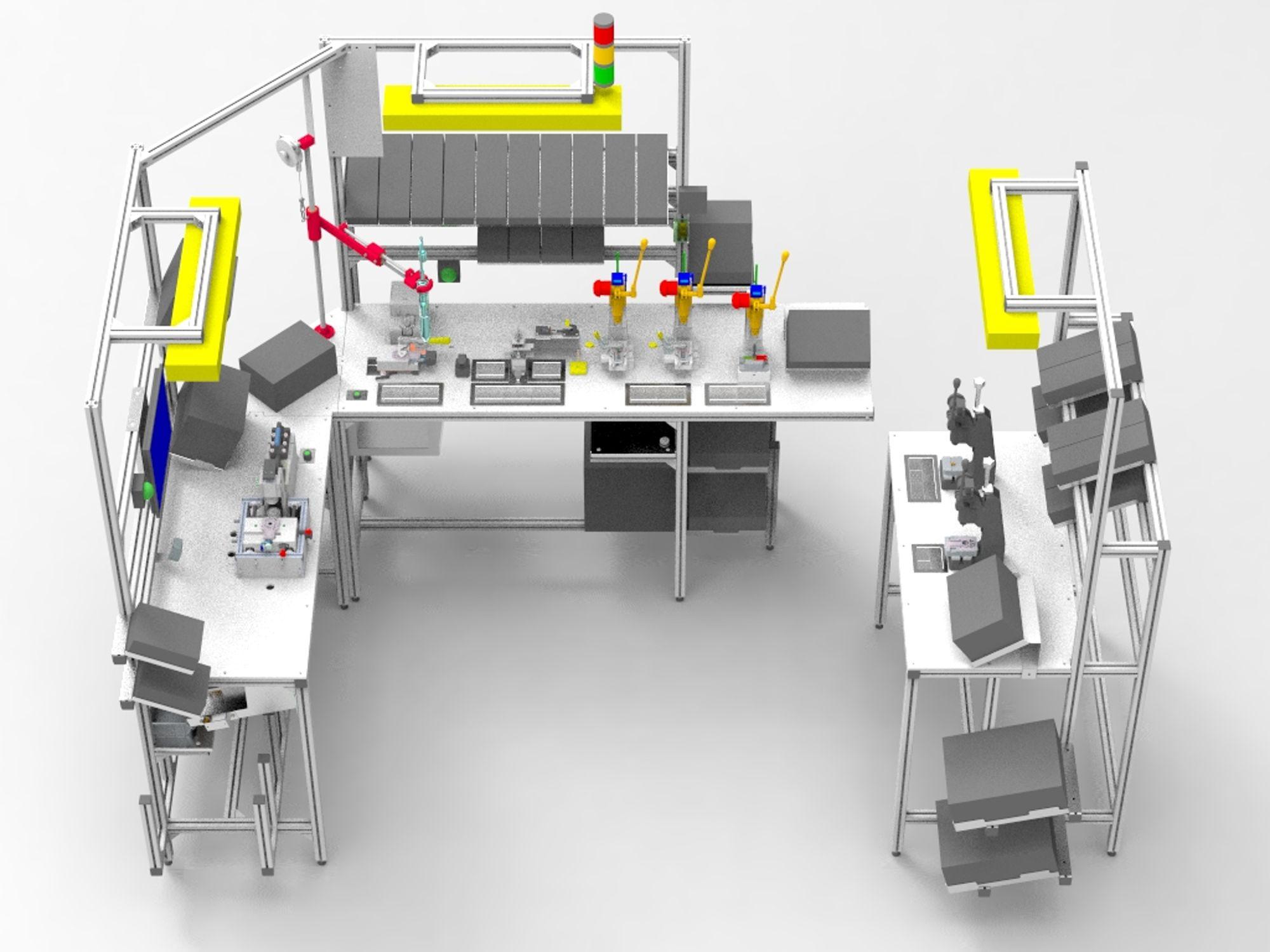

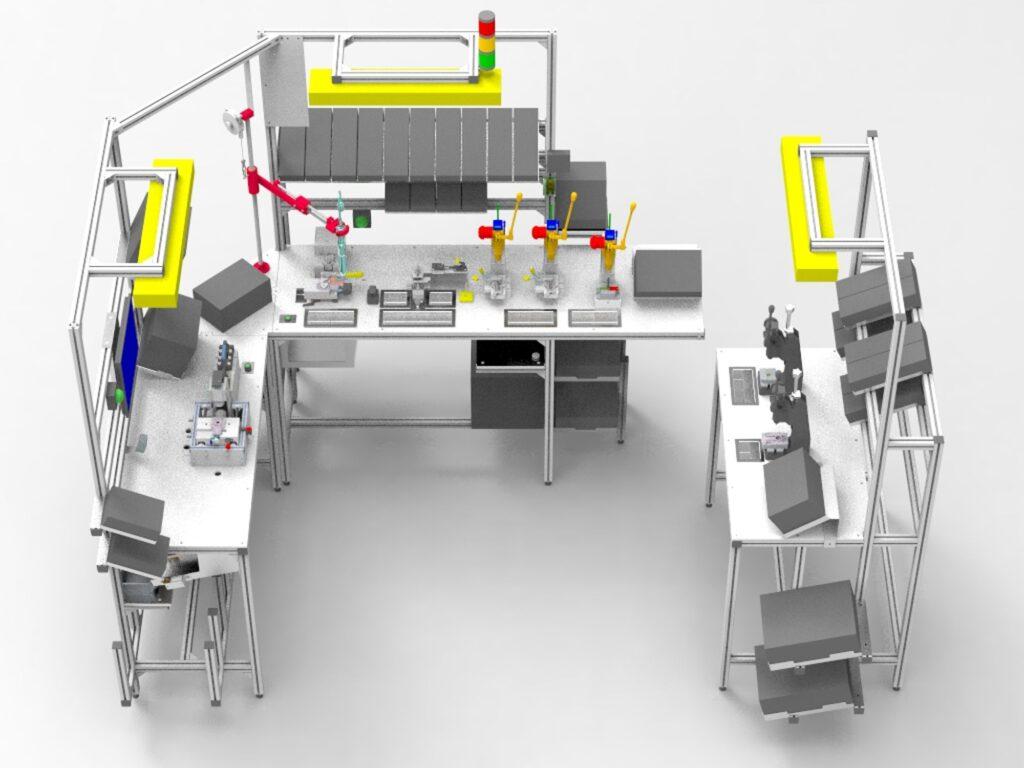

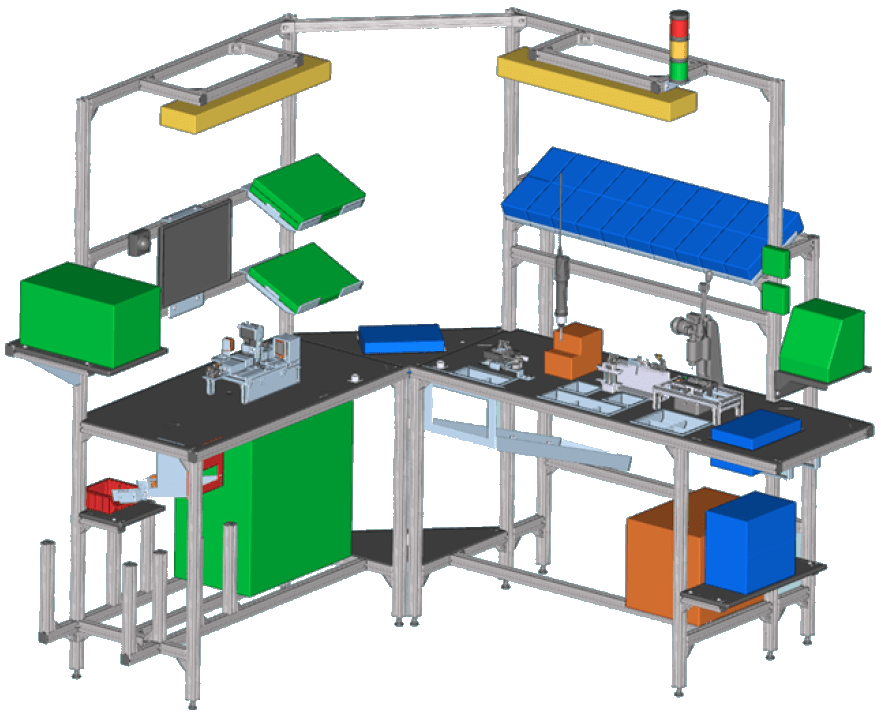

Our devices can be used in industries where the production process needs to be automated. Switching from manual to automated will always make production more efficient because:

Nowadays, no company can do without quality production lines. It is these that will ensure the all-important industrial automation and thus higher production capacity, quality, reliability, efficiency, and competitiveness.

Production lines are designed to optimize production and minimize costs, which in turn increase production efficiency. Thanks to their flexibility, they can be easily modified to produce new products, allowing production to be quickly and efficiently adapted to new requirements and thus take advantage of market opportunities.

Production lines also minimize the number of operators. This will reduce production costs as well as the risk of human error and increase production safety. These lines also reduce waste, which will be reflected in the cost and amount of material consumed.

We design production lines with varying degrees of automation:

An integral part of each line can be databases of products and production data, a traceability system for individual workplaces, where they continuously store the results of their testing and other information. This data can be connected to the superior system (ERP, MES, etc.).

Visualization of individual processes is performed on screens, touch panels, or HMI panels. Of course, there can be in different language versions.

We will design a production line for your:

We offer complete project processing according to customer specifications and requirements:

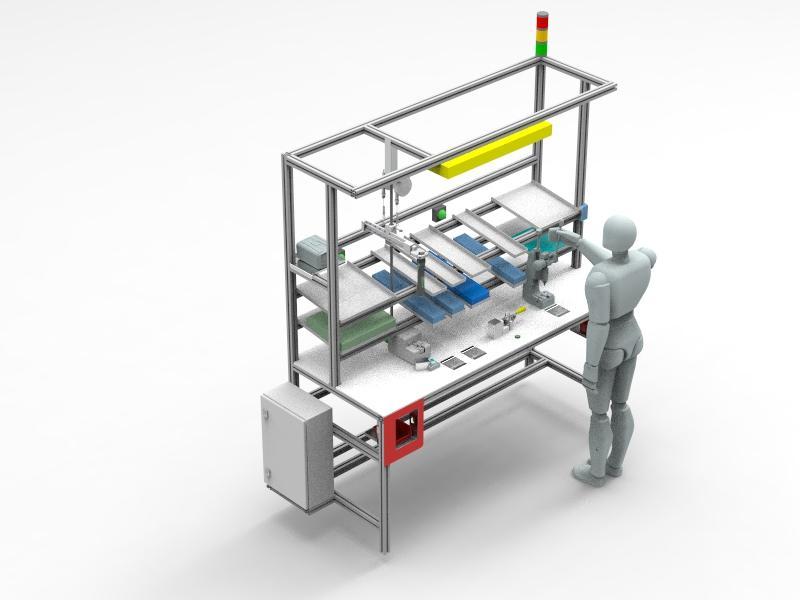

Single-purpose machines are devices optimized to produce one or several similar products in large batches. These machines are simple to operate and maintain. Their advantage is also the possibility of 24/7 operation and thereby handle a large amount of work in a short amount of time. Thanks to them, you can increase the speed and efficiency of production and thus the performance of the entire company.

Single-purpose devices are very reliable and easy to maintain. Thanks to their precise and high-quality design, they do not experience as much wear as universal machines and require less maintenance and fewer repairs. The machine can thus function in continuous operation throughout the life of the project.

The device can be implemented with different degrees of automation:

An integral part of each line can be databases of products and production data, a traceability system for individual workplaces, where they continuously store the results of their testing and other information. This data can be connected to the superior system (ERP, MES, etc.).

Visualization of individual processes is performed on screens, touch panels, or HMI panels. Of course, there can be in different language versions.

We offer complete project processing according to customer specifications and requirements:

Robotized workplaces increase productivity and production accuracy and are able to operate 24/7. They can also perform dangerous or demanding tasks thereby increasing occupational safety and reducing costs.

The robotized workstation can either be part of a production line or stand as a separate station. They can replace physically demanding processes and operations that require accuracy and repeatability.

We have experience with ABB and Fanuc industrial and collaborative robots. We are able to supplement robotic workplaces with visual detection of 2D and 3D.

Application:

Control systems, software, and visualization are an integral part of any machine or device. They provide control, feedback, and workplace safety.

We design, integrate, and deliver systems according to customer requirements and needs. This delivery can be part of the entire production line or as a separate project.

In particular, we program:

We also provide and integrate database connections, traceability systems, or superior production software (ERP, MES).

With each SW we also supply visualization, which can be solved from light indicators to touch screen to HMI panels.

An essential part of the development of automation device is an effective design in the solid modeling software.

When manufacturing a production line, single-purpose device, or fixtures, creating a design in solid modeling software is one of the first stages of a project.

We use Solid Edge software for design, development, modeling, presentation, and production documentation. This software addresses all stages of product development and production and combines the speed and simplicity of direct modeling with the flexibility of parametric design thanks to its synchronous technology.

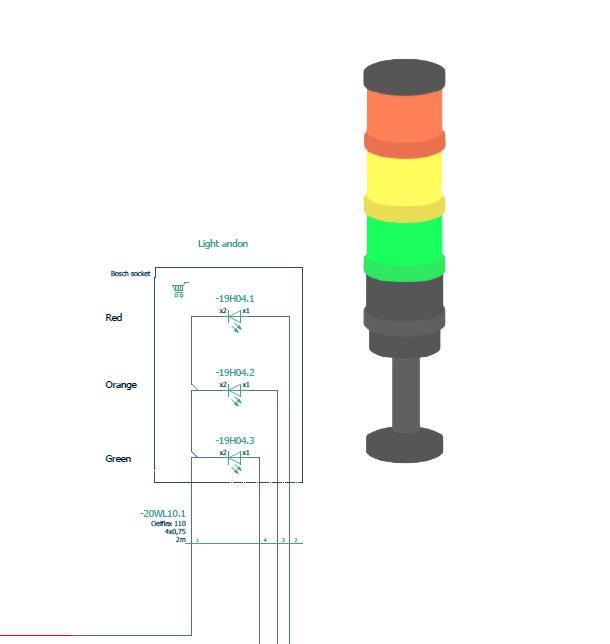

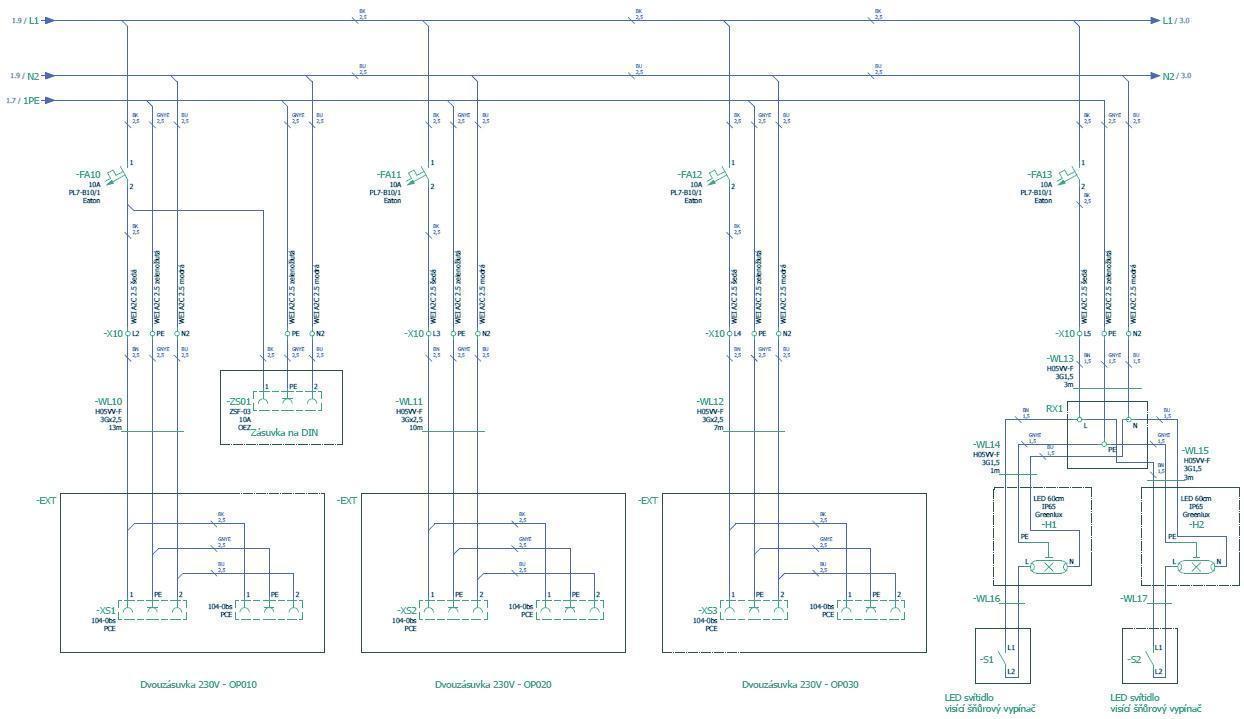

Electronic documentation is another of the necessary elements of our projects.

To keep our solutions accurate and detailed, we use powerful and innovative EPLAN software. This documentation primarily contains circuit diagrams, electrical components, parts lists, documentation for the construction of switchboards, and other elements for subsequent processing.

EPLAN provides software and services for the fields of electrical engineering, automation, and mechatronics.

Service and maintenance are also an indispensable part of any manufactured and delivered device.

Together with the supply of production lines, single-purpose devices, or fixtures, we offer contract service, warranty service, and post-warranty service. We always ensure that our proposed devices works for as long as possible without failures or major downtime.

We also offer service and maintenance of both mechanical components and software of your devices.